ABOUT MIRAMAR METAL PROCESSING

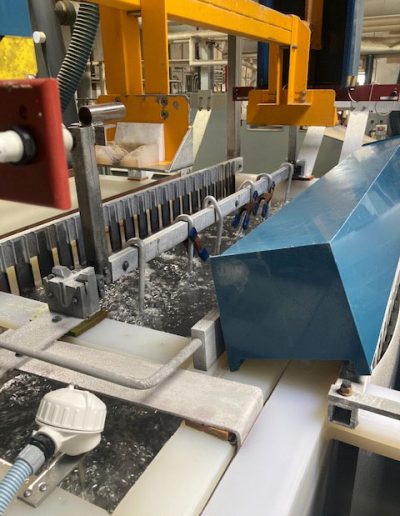

Miramar Metal Processing of San Diego, Inc. (MMP) is a state of the art metal processing facility located in San Diego, California. With years of combined metal finishing experience, we have a comprehensive offering of superior, professional metal coating and metal finishing services all under one roof.

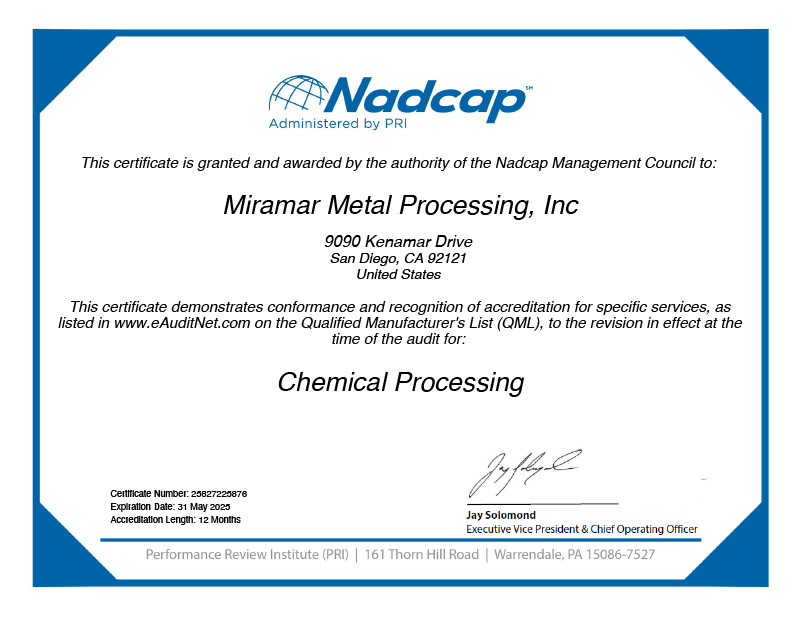

Miramar Metal Processing is proud to announce a milestone in our company history – we have received Nadcap® accreditation for Aerospace Quality System (AC7004) and Chemical Processing. This is an important mark of recognition in our industry.

Nadcap accreditation is globally recognized as a hallmark of quality, and is a major accomplishment. For many years, the aerospace industry has incorporated Nadcap into its approach for handling risk, as it demonstrates compliance to industry standards and customer requirements.

Top Shops

2018 Award

Top Shops

2020 Award

Top Shops

2021 Award

Top Shops

2023 Award

Top Shops

2024 Award

We are customer driven and committed to offering:

Top Quality

Proprietary Specialty Finishes

Prompt turnaround and delivery times

Competitive Pricing

Excellence in Client Service

Located in San Diego, our facility is conveniently situated in the Miramar area, with easy access to the I-5, I-805 and I-15 freeways and we service all of San Diego County as well as Riverside, Los Angeles and Orange County.

We also accept work from out-of-state clients.

We offer pick-up and delivery within a limited area.

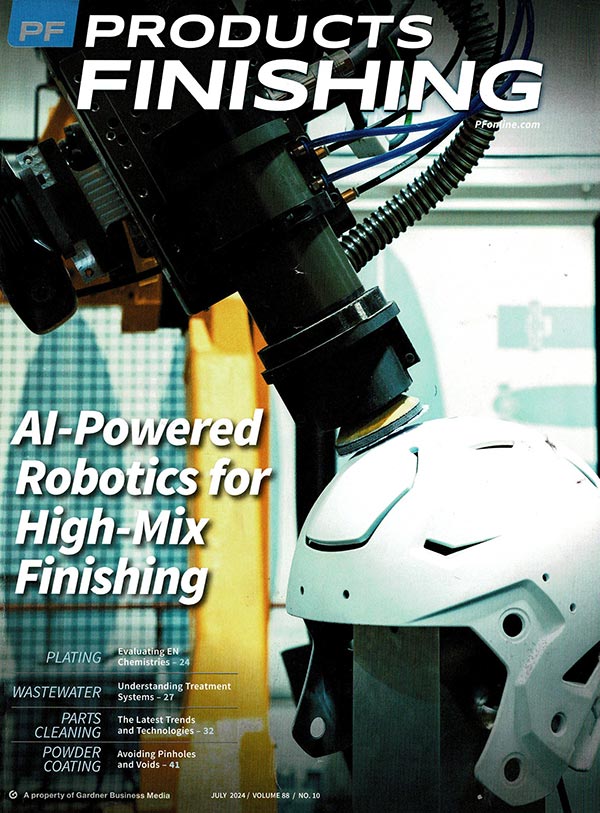

Miramar Metal in the News

Finisher’s ‘Top Shop’ Status Attracts Business

Featured in pfonline.com – by Lori Beckman

Striving for recognition as one of the Top Shops, Miramar Metal Processing won its first PF Top Shops award in 2018 and four times since then.

When its customers, especially those in the aerospace and defense sector, started to require higher product standards, MMP began focusing on upgrading its quality systems. As a result, it earned its ISO certification and most recently its NADCAP certification.

SERVICES

AC-130-2 Surface Pre-Treatment

AC-130-2 surface pre-treatment delivers equivalent performance to PAA — in less time. The water-based sol-gel system will enhance adhesion between aluminum alloys, steel, titanium and composites and help reduce overall operating costs.

EW-5000 Structural Adhesive Primer

M™ Scotch-Weld™ Structural Adhesive Primer EW-5000 meets multiple customer specs in the aerospace industry. It dries evenly in ambient temperatures and can be handled prior to the bake cycle, which improves shop handling over competitive solvent-based systems.

Anodize Type II

Aluminum Anodize Type II is an electrolytic process that transforms the surface of aluminum into an aluminum oxide coating. The product becomes more durable, improving corrosion and abrasion resistance. Due to the porous nature of the oxide coating, the material now becomes a blank canvas where it is possible to dye it in a variety of different colors, or it may also be silkscreened and imprinted with graphics, as required.

Anodize Type III

Anodize Type III (hard coat) is an electro-chemical process that transforms the surface of the metal into an aluminum oxide coating. Amongst the benefits of Type III Anodizing is superb abrasion and wear resistance, and excellent dielectric properties.

Bright Dip Anodizing

Bright Dip or Chemical Polishing is a pre-treatment used to enhance the sheen of aluminum. Anodizing the product after bright dipping will protect the metal against corrosion and preserve the luster of the metal.

Phosphoric Acid Anodizing (PAA)

Also known as the Boeing process, PAA is recognized as an excellent preparation for adhesive bonding in the aerospace industry. The oxide film formed during the anodizing process has greater durability under adverse conditions than films formed in chromic acid...

Sulfuric Acid Anodizing Type IIB

Type IIB is a thin sulfuric acid anodizing, for use as a non-chromate alternative for Type I and Type IB coatings, where corrosion resistance, paint adhesion and fatigue resistance is required. Request Quote

PTFE Impregnated Anodizing

PTFE is a process which meets the requirements of MIL-A-63576. During the process, an aluminum oxide coating is impregnated with PTFE to increase the wear and corrosion resistance, hardness and lubricity of anodized aluminum. It transforms the surface of aluminum into...

Passivation

Passivation is an immersion process where the free iron is chemically removed from the surface of stainless steel or various other alloys. The removal of superficial iron is performed by chemical dissolution. It removes the surface contaminant without affecting the stainless steel.

Paint, Primers & Adhesive Primers

With a renewed and upgraded paint shop, we have three paint booths and two ovens and are well equipped to handle a variety of regular and special needs for either liquid paint or powder.

BR-127 Adhesive Bond Primer

The Primer BR® 127 is a modified epoxy primer. It is the industry standard for high-performance corrosion primers and has been used in virtually every commercial aircraft built since its introduction. This material can be used with essentially all 250°F (121°C) film...

Chem Film

Chemical film coating, also referred to as Chem Film applies a chromate conversion coating on aluminum, producing a finish which protects from corrosion, conducts electricity and allows for good paint adhesion.

Dry Film

A Dry Film lubricant is used to prevent galling and seizure of metals. It is a modified paint where the pigment has been substituted or exchanged for a powdered lubricant such as graphite or moly disulfide.

Electropolishing

Electropolishing is an electrochemical process that removes material from a metallic workpiece, reducing the surface roughness by leveling micro-peaks and valleys, improving the surface finish. It is used to polish, passivate, and deburr metal parts and may be used in lieu of abrasive fine polishing.

FPL Etching

FPL Etching was developed by Forest Products Laboratory, hence the commonly used name of FPL etch. FPL Etching provides increased bond durability. The etched aluminum surface consists of ‘whisker-like’ protrusions, which are important in ensuring bond strength and...

Glass Bead Blasting

As a key step in the preparation of parts for assembly, plating, anodizing, painting or coating, Glass Bead Blasting is a useful method of cleaning to remove all foreign matter from metal such as scale, corrosion, paint, carbon and epoxy etc., without chemical stripping.

Symcoat HT-500 (Proprietary Finish)

SYMCOAT HT500 is a proprietary process used for mold release applications. It can be applied to molds made from different metals including aluminum, steel and stainless steel. It is designed to withstand temperatures up to 750ºF intermittently or it can be used continuously at temperatures up to 500ºF.

Symcoat HCT (Proprietary Finish)

SYMCOAT HCT is a proprietary process which meets the requirements of MIL-A-63576. During the process, an aluminum oxide coating is impregnated with PTFE to increase the wear and corrosion resistance, hardness and lubricity of anodized aluminum. It transforms the surface of aluminum into a ceramic type of material, which cannot be scratched or nicked by ordinary means.

TCP-HF

TCP-HF was developed and patented by the Department of Defense, US Navy. It is a trivalent chromate based coating aimed at replacing Hexavalent Chromates, and outperforms all other trivalent products tested.

Masking

Masking is employed in most any metal finishing operation where only a specifically defined area of the surface of a part must be exposed to a process. Conversely, masking may be employed on a surface where treatment is either not required or must be avoided.