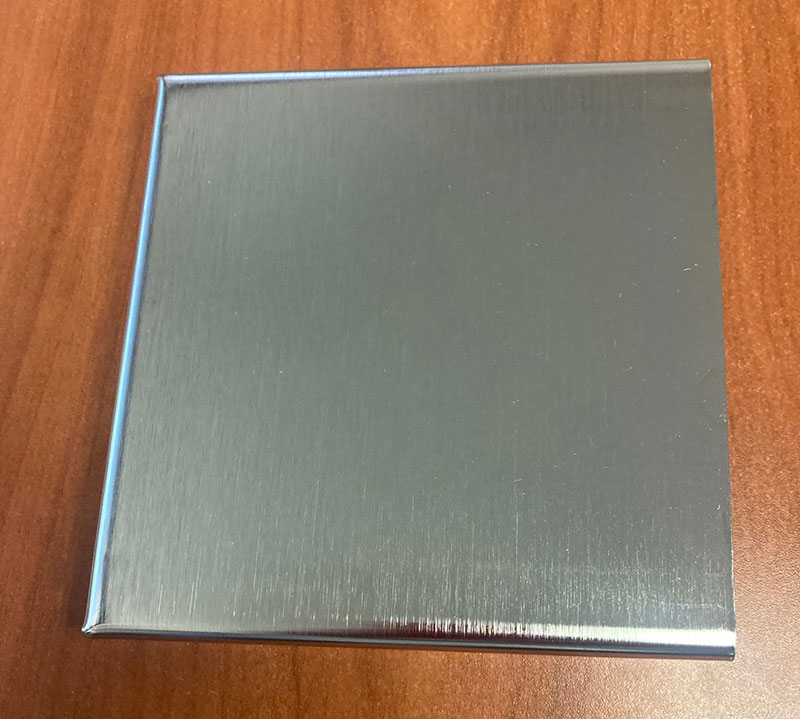

Electropolishing is an electrochemical process that removes material from a metallic workpiece, reducing the surface roughness by leveling micro-peaks and valleys, improving the surface finish. It is used to polish, passivate, and deburr metal parts and may be used in lieu of abrasive fine polishing.

Electropolishing can be used to sterilize workpieces and the process plays an essential role in the food, medical, and pharmaceutical industries. It is commonly used in the post-production of large metal pieces.

While nearly any metal may be electropolished, the most-commonly polished metals are 300- and 400-series stainless steel.

- The results are considered to be aesthetically pleasing.

- It creates a clean, smooth surface that is easier to sterilize.

- It allows for polishing of areas that are inaccessible by other polishing methods.

- Removes a small amount of material from the surface of the parts, while also removing small burrs or high spots.

- Superior level of passivation on stainless steel alloys.