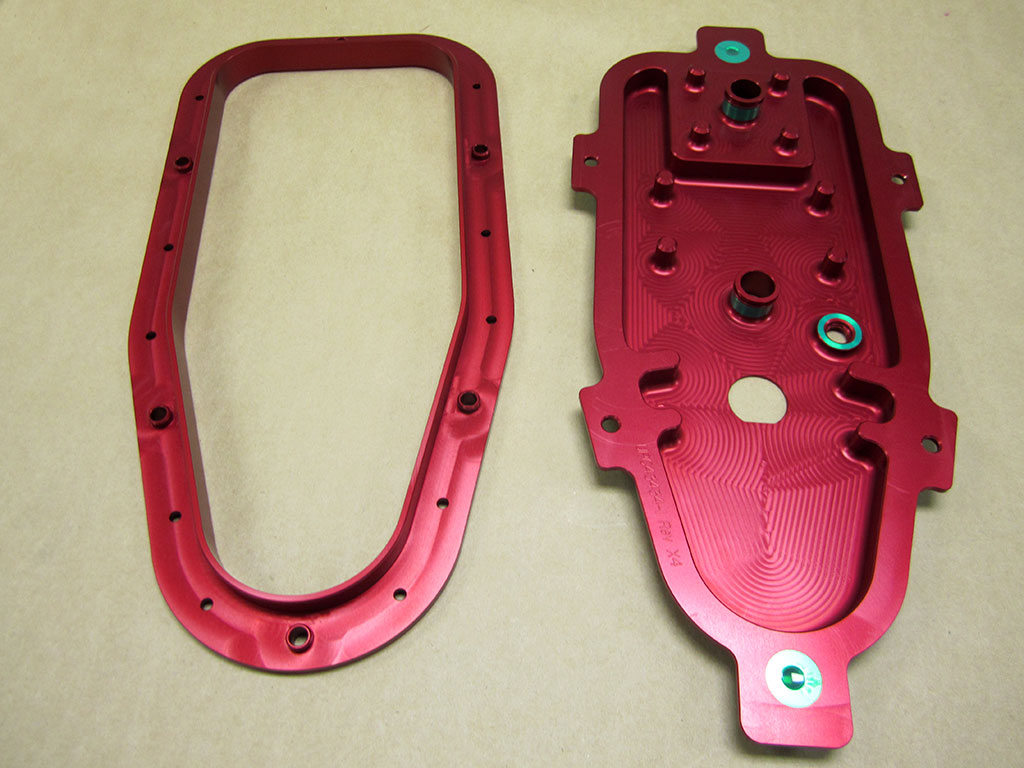

Aluminum Anodize Type II is an electrolytic process that transforms the surface of aluminum into an aluminum oxide coating. The product becomes more durable, improving corrosion and abrasion resistance. Due to the porous nature of the oxide coating, the material now becomes a blank canvas where it is possible to dye it in a variety of different colors, or it may also be silkscreened and imprinted with graphics, as required.

Type II Anodizing is generally used to visually enhance a product. Typical applications include decorative finishes, light reflectors, flash lights, automotive trim, sporting equipment, architectural trim, pens and other promotional items.

With Type II Anodizing it is important to note:

• Maximum thickness is 0.0008 inches

• Class 1 refers to non-dyed

• Class 2 refers to dyed

We offer several standard colors.

Custom colors are available on request.

We run regular testing to ensure light fastness of dyes used for a Rating of 8 with Mil Spec 8625.