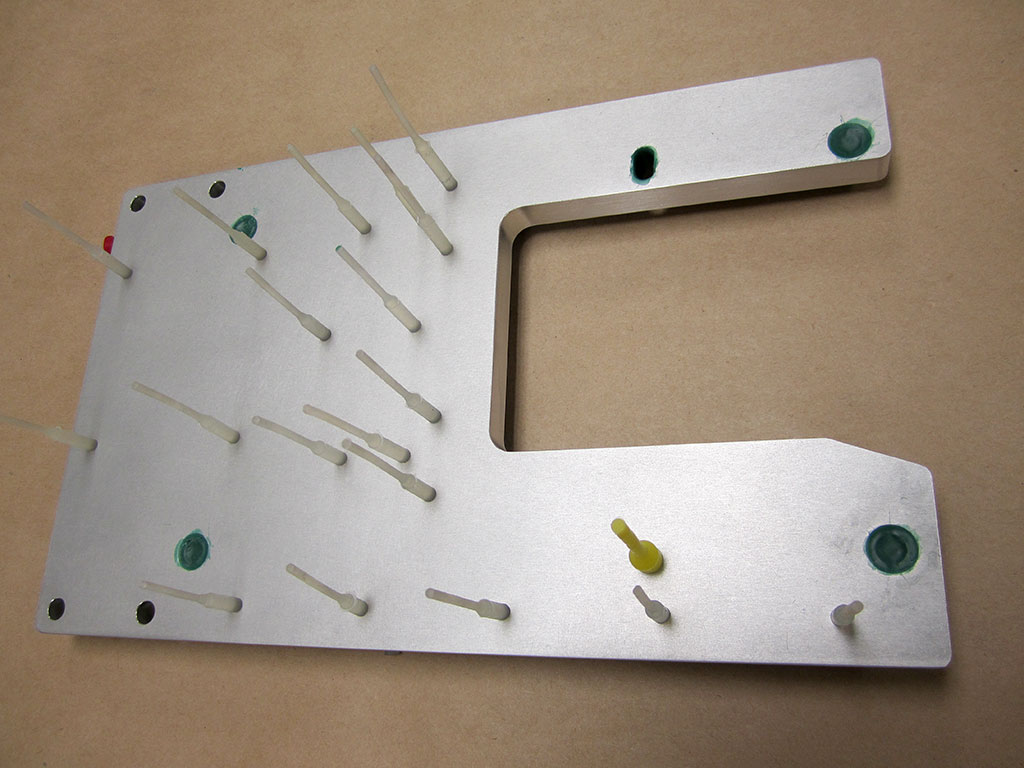

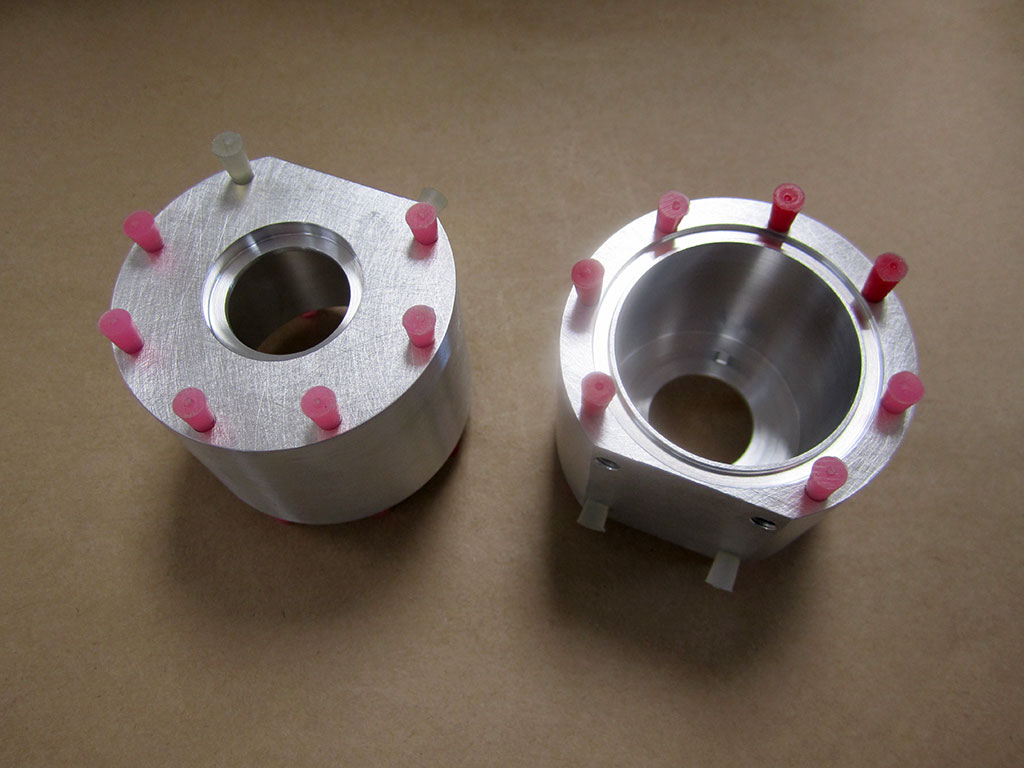

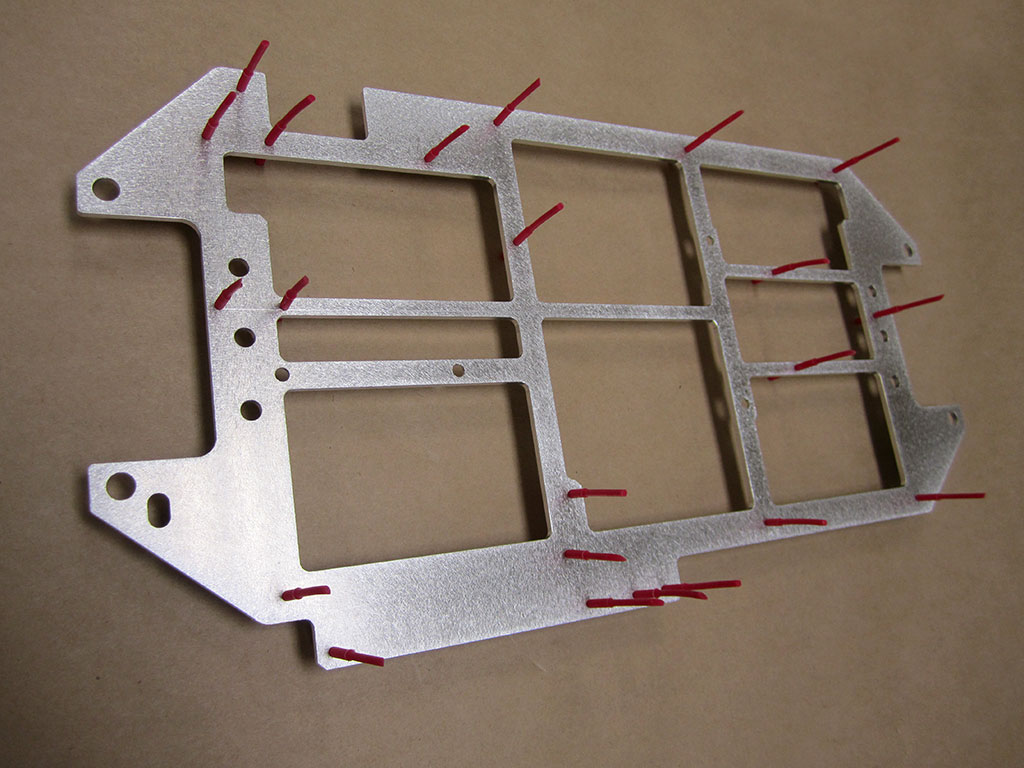

Masking is employed in most any metal finishing operation where only a specifically defined area of the surface of a part must be exposed to a process. Conversely, masking may be employed on a surface where treatment is either not required or must be avoided.

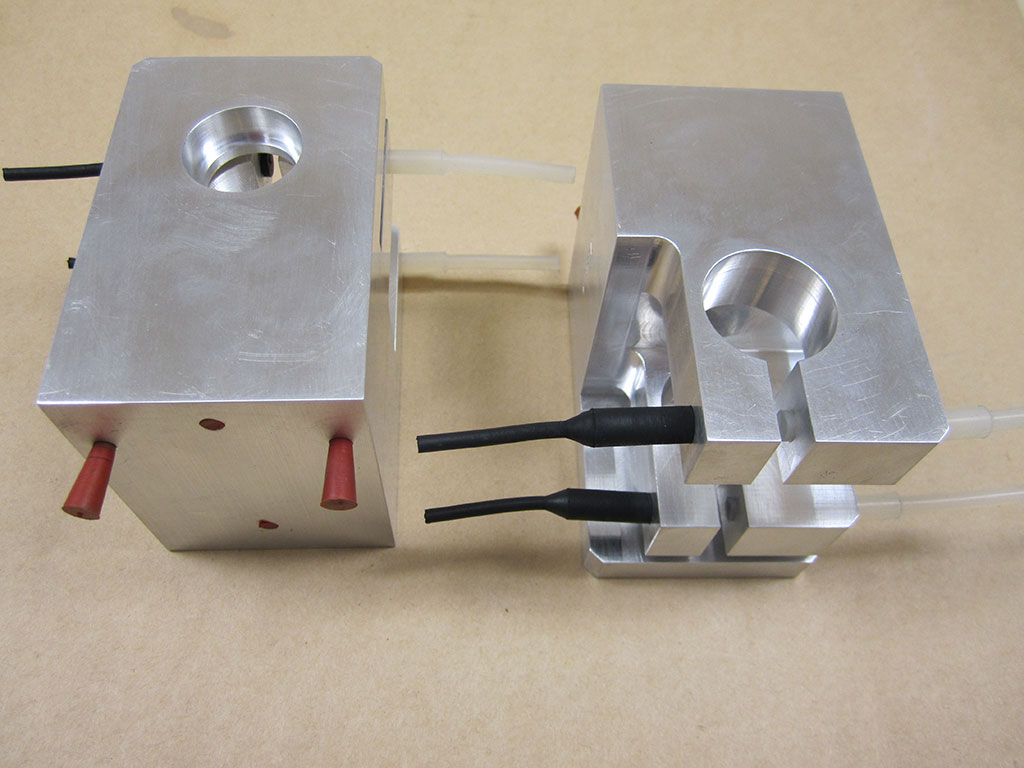

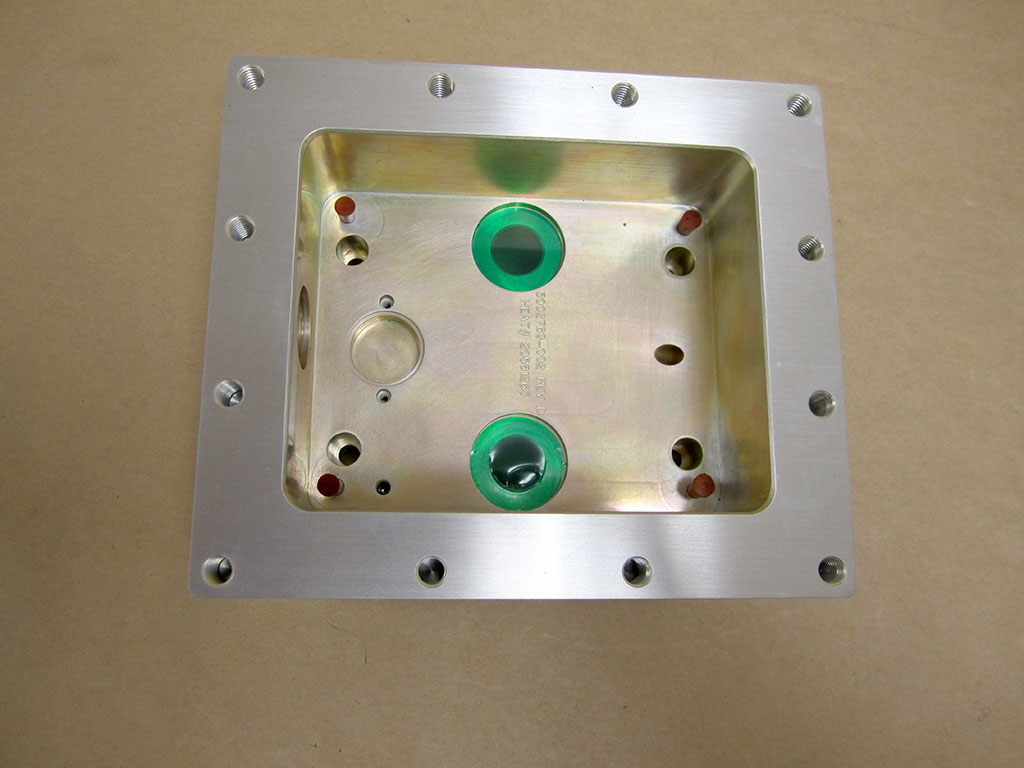

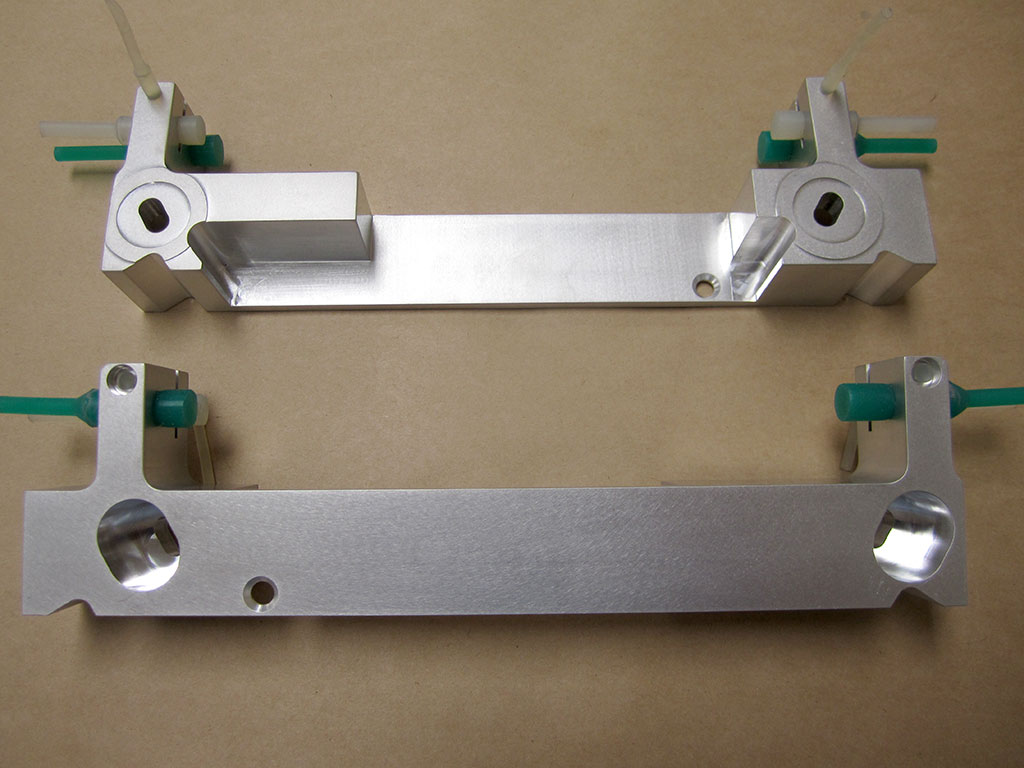

During the anodizing process, products comprised of more than one metal will require masking as different metals (steel, brass, bronze) or any form of plating will be burnt off in the anodizing tank unless masked.

Masking is also required where no build up is desired or when a part needs both anodizing and chemical conversion / Chem Film.

• All threaded holes, (1/4 “or smaller) are typically masked when hard-coating unless otherwise specified.

• Holes with heli-coils must be masked.