by superpotion | Jul 10, 2024 | Uncategorized

This competitive California finisher made it a goal to become a PF Top Shop. After earning the recognition, the company experienced an immediate increase in business and a challenge to obtain certifications.

by superpotion | Apr 27, 2022 | Services

AC-130-2 surface pre-treatment delivers equivalent performance to PAA — in less time. The water-based sol-gel system will enhance adhesion between aluminum alloys, steel, titanium and composites and help reduce overall operating costs.

by superpotion | Apr 27, 2022 | Services

M™ Scotch-Weld™ Structural Adhesive Primer EW-5000 meets multiple customer specs in the aerospace industry. It dries evenly in ambient temperatures and can be handled prior to the bake cycle, which improves shop handling over competitive solvent-based systems.

by superpotion | Jun 28, 2019 | Services

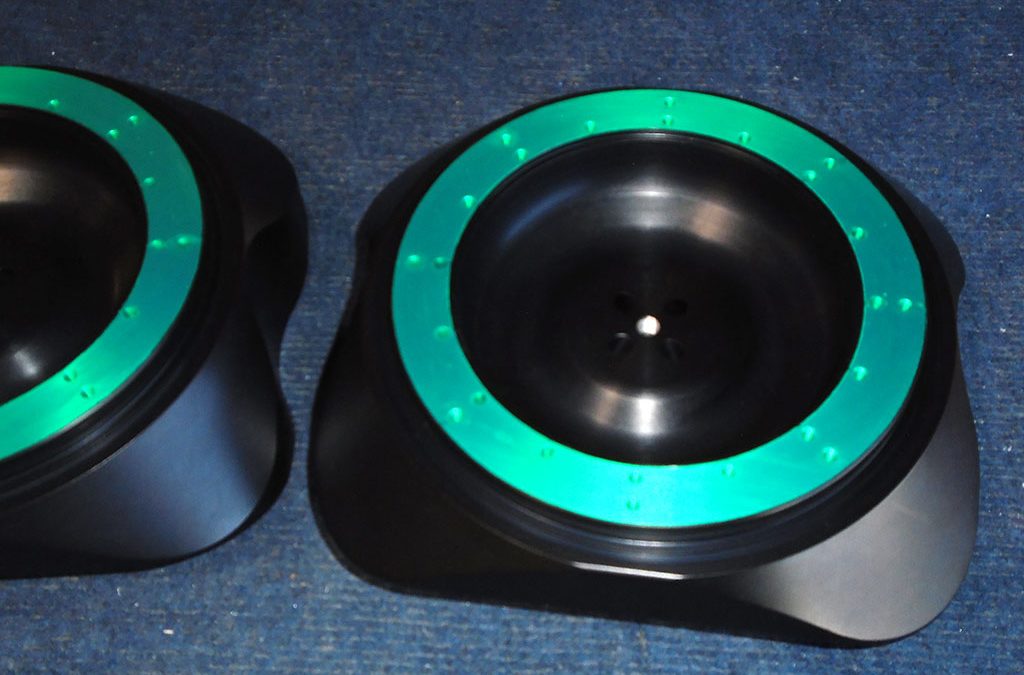

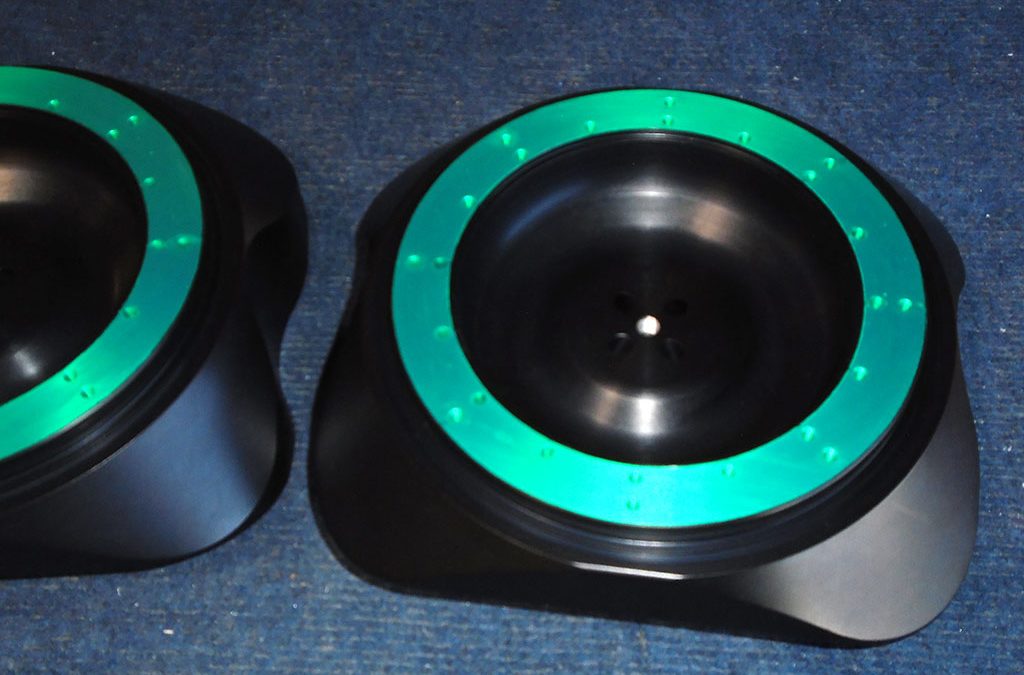

Aluminum Anodize Type II is an electrolytic process that transforms the surface of aluminum into an aluminum oxide coating. The product becomes more durable, improving corrosion and abrasion resistance. Due to the porous nature of the oxide coating, the material now becomes a blank canvas where it is possible to dye it in a variety of different colors, or it may also be silkscreened and imprinted with graphics, as required.

by superpotion | Jun 28, 2019 | Services

Anodize Type III (hard coat) is an electro-chemical process that transforms the surface of the metal into an aluminum oxide coating. Amongst the benefits of Type III Anodizing is superb abrasion and wear resistance, and excellent dielectric properties.